In today’s fast-paced industrial landscape, the demand for robust and resilient materials is more significant than ever. Whether you’re dealing with petrochemical processes, marine environments, or any highly corrosive conditions, the integrity of your piping system can make or break your operations. That’s why choosing the right material for your pipe fittings is critical. Enter Inconel 600, a nickel-chromium alloy that stands tall as the champion for corrosive environments. In this blog, we’ll explore the reasons why Inconel 600 pipe fittings are the go-to solution for industries around the globe.

At Max Pipe Fittings, we believe in offering solutions that combine performance, durability, and reliability, especially when it comes to challenging environments. Here’s why Inconel 600 is a stellar choice for your pipe fitting needs.

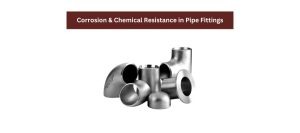

Exceptional Resistance to Corrosion

One of the foremost reasons why Inconel 600 is favored for pipe fittings in corrosive environments is its excellent resistance to a wide variety of corrosive agents. From acidic solutions to alkaline chemicals, Inconel 600 can withstand attacks that would severely degrade lesser materials.

Resistant to Acidic and Alkaline Environments: Inconel 600 can easily resist corrosion in both highly acidic environments, such as sulfuric acid or hydrochloric acid, and in alkaline solutions like sodium hydroxide. This makes it an ideal choice for industries that require piping to withstand aggressive chemical exposure.

Oxidation Resistance at High Temperatures: The alloy performs well even in temperatures that can soar up to 2000°F (1093°C). Its unique composition allows it to form a protective oxide layer on the surface, preventing oxidation that would otherwise weaken the material. Industries dealing with high-temperature processes, such as heat treatment and petrochemical plants, benefit enormously from this quality.

Superior Strength at High Temperatures

Inconel 600 isn’t just resistant to corrosive environments; it’s also capable of maintaining its strength and structural integrity at elevated temperatures. This is particularly important for applications in heat exchangers, nuclear reactors, and chemical plants, where high temperatures are common.

Thermal Stability: The alloy retains its mechanical properties even when exposed to extreme heat for prolonged periods. Whether you’re operating at high temperatures or dealing with rapid thermal cycling, Inconel 600 fittings ensure that your piping system remains secure and functional.

Creep Resistance: Creep deformation, which occurs when materials are subjected to stress at high temperatures, is a concern for many alloys. Inconel 600, however, has high resistance to creep, making it ideal for applications involving prolonged exposure to heat.

Versatility Across Industries

Inconel 600’s unique properties make it one of the most versatile alloys available for pipe fittings. From aerospace to chemical processing, its ability to resist corrosion and maintain strength under heat makes it an indispensable material in several critical sectors.

Petrochemical and Chemical Processing: In these industries, pipe fittings are constantly exposed to harsh chemicals, aggressive acids, and fluctuating temperatures. Inconel 600 is a perfect fit due to its ability to resist cracking under such extreme conditions, providing a long-lasting solution.

Aerospace Applications: High-temperature environments aren’t restricted to just chemical plants. In aerospace, where engines and exhaust systems regularly reach scorching temperatures, Inconel 600 plays a pivotal role in ensuring safe and efficient operations. Its high creep and oxidation resistance contribute significantly to reducing the risk of failure.

Power Generation: In nuclear and thermal power plants, where both corrosive fluids and high temperatures are present, Inconel 600 pipe fittings ensure reliable performance, reducing the need for constant maintenance or replacement.

Cost-Effectiveness in the Long Run

While Inconel 600 pipe fittings may initially appear more expensive than traditional materials like stainless steel or other nickel alloys, the long-term cost benefits are undeniable. Due to its superior durability and resistance to corrosion, industries using Inconel 600 experience fewer downtimes, maintenance costs, and replacement needs.

Minimal Downtime and Maintenance Costs: Inconel 600’s ability to endure harsh environments means less wear and tear on your piping system. This translates to fewer repairs and lower operational costs over time. By opting for a high-performance alloy like Inconel 600, you reduce the need for constant maintenance, allowing your operations to continue without costly interruptions.

Longevity and Durability: Industries operating in aggressive environments often find themselves needing to replace pipe fittings due to corrosion or high-temperature wear. Inconel 600 offers a long-lasting solution that reduces the frequency of replacements, making it a more cost-effective option in the long run.

Ease of Fabrication and Installation

In addition to its outstanding performance in corrosive and high-temperature environments, Inconel 600 is also easily fabricated. Its ductility and weldability make it a popular choice for pipe fittings that need to be custom-made or adjusted on-site.

Weldability: Inconel 600 can be welded using standard methods, including TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas), without the risk of cracking or losing its corrosion-resistant properties. This is crucial for industries that require precision during the installation process.

Formability: Whether you’re shaping complex pipe fittings or cutting and bending for specific dimensions, Inconel 600’s formability makes it an easy material to work with, ensuring a smooth and efficient installation process.

Max Pipe Fittings: Your Trusted Partner

At Max Pipe Fittings, we understand the critical importance of choosing the right materials for your piping systems. With our expertise in providing high-quality Inconel 600 pipe fittings, we ensure that your operations continue smoothly, no matter how harsh the environment.

Expert Consultation: Our team of experts is always ready to provide guidance on choosing the right materials and solutions for your specific needs. Whether you’re dealing with highly corrosive chemicals or extreme temperatures, we can help you make informed decisions.

Quality Assurance: At Max Pipe Fittings, quality is our top priority. We source only the best Inconel 600 alloys, ensuring that every fitting meets industry standards and exceeds your expectations.

Customized Solutions: Need a custom fitting? We’ve got you covered. Our fabrication process allows us to create pipe fittings tailored to your exact specifications, ensuring a perfect fit every time.

Conclusion

Inconel 600 is a powerhouse alloy that has proven itself time and again in the most challenging environments. From its exceptional resistance to corrosion and oxidation to its strength at high temperatures, it’s a material that offers both reliability and durability. At Max Pipe Fittings, we take pride in offering top-notch Inconel 600 pipe fittings that help industries thrive even in the most corrosive environments.