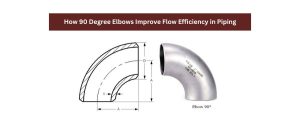

Discover everything about the essential 90 degree elbow in piping systems, a key fitting that expertly changes the flow direction. Our guide covers the basics, types, and specifications of 90-degree elbows, ensuring you have the knowledge to make informed choices. Perfect for professionals and enthusiasts alike looking to understand piping system components.

What is a 90 Degree Elbow?

A 90-degree elbow pipe fitting is crucial for connecting pipes at a right angle, optimizing fluid and gas flow direction in plumbing, HVAC, and industrial systems. This essential component ensures seamless flow redirection, making it indispensable in managing efficient piping systems across various applications.

Types of 90 Degree Elbows

90-degree elbows come in various types, each designed to suit specific needs and applications. The main types include:

- Short Radius (SR) 90 Degree Elbow:

- Description: This type has a radius equal to the pipe diameter (1D). It is compact and used in tight spaces.

- Applications: Suitable for high-pressure applications where space is limited.

- Long Radius (LR) 90 Degree Elbow:

- Description: This elbow has a radius that is 1.5 times the pipe diameter (1.5D). It provides a smoother flow with less resistance.

- Applications: Commonly used in low-pressure applications where flow efficiency is a priority.

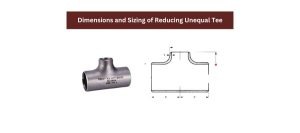

- Reducing 90 Degree Elbow:

- Description: This type connects pipes of different diameters, reducing the size of the pipe while changing the direction.

- Applications: Useful in systems where the pipe size needs to be decreased while maintaining directional change.

- Threaded 90 Degree Elbow:

- Description: This elbow has threads on both ends, allowing it to be screwed onto pipes without the need for welding.

- Applications: Ideal for low-pressure applications and systems that require frequent disassembly.

- Socket Weld 90 Degree Elbow:

- Description: This type has a socket into which the pipe is inserted and then welded. It provides a secure and leak-proof connection.

- Applications: Used in high-pressure and high-temperature systems.

- Butt Weld 90 Degree Elbow:

- Description: This elbow is welded directly to the pipe, providing a strong and permanent joint.

- Applications: Suitable for critical and high-stress applications, such as in the oil and gas industry.

Specifications of 90 Degree Elbows

When selecting a 90 degree elbow for a specific application, it is crucial to consider various specifications, including:

- Material:

- Common materials include stainless steel, carbon steel, alloy steel, and plastic (PVC, CPVC).

- Material selection depends on the fluid or gas being transported, temperature, and pressure requirements.

- Size:

- Elbows are available in a range of sizes, typically specified by the nominal pipe size (NPS).

- Sizes range from small diameters (1/8 inch) to large diameters (up to 48 inches or more).

- Pressure Rating:

- The pressure rating indicates the maximum pressure the elbow can withstand.

- Common ratings include Class 150, Class 300, Class 600, and higher, depending on the application.

- Thickness (Schedule):

- The schedule number (e.g., Schedule 40, Schedule 80) indicates the wall thickness of the elbow.

- Thicker walls are used for higher pressure applications.

- Standards and Codes:

- 90-degree elbows must comply with industry standards and codes, such as ASME B16.9, ASTM, and ANSI.

- Compliance ensures quality, safety, and compatibility with other piping components.

Applications of 90-Degree Elbows

90-degree elbows are used across a wide range of industries and applications, including:

- Plumbing: To navigate around obstacles and change pipe directions in residential and commercial buildings.

- HVAC Systems: To direct airflow in heating, ventilation, and air conditioning systems.

- Industrial Piping: In oil and gas, chemical processing, and power generation plants to manage fluid and gas flow.

- Water Treatment: In filtration and water distribution systems.

Conclusion

The 90-degree elbow is an indispensable component in piping systems, offering flexibility and efficiency in directing flow. By understanding the various types and specifications, engineers and designers can select the right elbow for their specific needs, ensuring optimal performance and longevity of the system. Whether for residential plumbing or industrial applications, the 90-degree elbow remains a cornerstone of effective fluid and gas management.