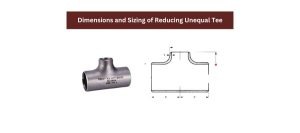

In industrial piping systems, fittings play a crucial role in connecting different pipe sections, redirecting flow, and controlling pressure. Among these fittings, the Reducing Unequal Tee stands out for its ability to connect pipes of varying diameters while also allowing a branch connection at 90 degrees. To ensure efficiency and leak-free systems, understanding the dimensions and sizing of this specific fitting is essential.

This blog offers a complete overview of the Reducing Unequal Tee including dimensional standards, sizing practices, applications, and selection criteria.

What is a Reducing Unequal Tee?

A Reducing Unequal Tee is a pipe fitting that features three outlets: one inlet and two outlets at 90-degree angles, with the branch having a smaller diameter than the main run. It is primarily used in pipelines where a reduced flow needs to be branched off from the main line.

It differs from a standard tee in that not all three ends have the same diameter. This distinction allows engineers to design systems with varying pipe sizes while maintaining optimal flow and pressure conditions.

Importance of Proper Dimensions and Sizing

Accurate sizing and dimensioning of a Reducing Unequal Tee are critical for several reasons:

- Ensures compatibility with existing pipelines

- Prevents pressure loss and turbulence

- Reduces risk of leakage and pipe failure

- Meets safety and industry standards

- Facilitates smooth installation and maintenance

Improper dimensions can lead to mismatches that affect performance and increase repair costs.

Key Dimensions to Consider

When working with Reducing Unequal Tees, the following dimensions must be carefully evaluated:

- Main Run Diameter (N1 & N2):

This refers to the larger diameter of the straight run, often consistent on both sides. - Branch Diameter (N3):

The smaller outlet connected at a 90-degree angle to the main run. This is the reduced connection. - Center-to-End Distance (C1 & C2):

These are the distances from the center of the fitting to the end of the run and branch outlets, respectively. - Wall Thickness (WT):

Usually matches the Schedule (SCH) of the piping system—e.g., SCH 40, SCH 80. - Overall Length:

The total length from end to end of the main run helps determine installation spacing.

Sizing Chart for Reducing Unequal Tee

Here’s an example of standard dimensions based on ASME B16.9 for butt-welded tees. (Note: Always refer to manufacturer or project-specific charts.)

| Main Size (in) | Branch Size (in) | Center-to-End Run (C1) | Center-to-End Branch (C2) |

|---|---|---|---|

| 4 | 2 | 76 mm | 51 mm |

| 6 | 3 | 95 mm | 57 mm |

| 8 | 4 | 108 mm | 64 mm |

| 10 | 6 | 127 mm | 76 mm |

| 12 | 8 | 152 mm | 89 mm |

Note: These are indicative values. Always verify against relevant standards and supplier data sheets.

Standards Governing Dimensions

Reductive tees are manufactured under several global standards, which govern not only material properties but also dimensional accuracy. These include:

- ASME B16.9: Factory-made wrought steel butt-weld fittings

- ANSI B16.11: Forged fittings, socket-welding and threaded

- MSS-SP 75: High-strength, wrought steel fittings

- DIN, EN, and ISO Standards: Often used in international or European applications

Compliance with these ensures the Reducing Unequal Tee will perform reliably in high-pressure and high-temperature environments.

Material Selection and Its Influence on Sizing

The choice of material can affect the wall thickness and therefore the overall dimensions of the tee. Common materials include:

- Carbon Steel: For general-purpose industrial applications

- Stainless Steel: Excellent corrosion resistance, especially for hygienic or marine applications

- Alloy Steel: Used in high-pressure or high-temperature systems

- Duplex/Super Duplex: For high strength and chemical resistance

Each material grade might require adjustments in thickness or reinforcement, depending on pressure ratings.

How to Measure and Select the Right Tee

- Measure Existing Pipe Diameters:

Identify the outer diameter (OD) of the main and branch pipes. - Determine Pipe Schedule:

Pipe schedule influences wall thickness. A SCH 80 pipe has a thicker wall than SCH 40 of the same diameter. - Use a Tee Matching the Main Run First:

Match the tee’s straight run to the larger pipe size, and then choose a branch that matches the smaller line. - Confirm with Project Specifications:

Always refer to design documents, CAD files, or engineering drawings for correct measurements. - Allow for Expansion and Stress:

Consider external factors like temperature-induced expansion and pipe support placement.

Applications Where Accurate Sizing Matters

- Oil & Gas: Where pressure drops must be minimized

- Water Treatment Plants: To manage flow reduction in distribution systems

- Chemical Processing: Ensures chemical flow integrity and minimizes risk

- HVAC Systems: For controlling airflow in ducted systems

- Fire Protection Systems: Properly sized tees ensure effective pressure delivery

Common Mistakes to Avoid

- Choosing a tee with mismatched branch size

- Ignoring wall thickness and pressure rating

- Using threaded fittings where welding is required

- Assuming dimensions are universal across materials

Avoiding these issues ensures smoother operation and reduces long-term costs.

Conclusion

Understanding the dimensions and sizing of a Reducing Unequal Tee is vital for any piping system. Whether you’re designing a new layout or upgrading an existing one, ensuring the right dimensions, materials, and standards will enhance the system’s efficiency, longevity, and safety.

From the main run to the reduced branch, every millimeter matters—especially in industrial settings where accuracy is non-negotiable. Use standardized sizing charts, refer to global standards, and consult with experienced manufacturers to make informed decisions.