In the world of pipe fittings, elbows play a crucial role in directing flow within piping systems. Among various types of elbows, Reducing Elbows and Welded Elbows serve distinct purposes, making it essential to choose the right one for your application. This blog will help you understand the differences, advantages, and best applications for both.

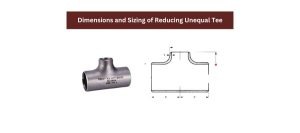

What is a Reducing Elbow?

A Reducing Elbow is a type of elbow fitting designed to connect pipes of different diameters while changing the direction of flow. It eliminates the need for an additional reducer, making it ideal for space-saving and efficient piping layouts.

Key Features of Reducing Elbow:

- Dual function: Changes both pipe size and flow direction.

- Compact design: Reduces the number of fittings in the system.

- Less turbulence: Provides smoother fluid transition.

- Available in multiple angles: Commonly found in 45° and 90° bends.

- Widely used in: Chemical processing, water treatment, and oil & gas industries.

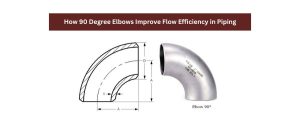

What is a Welded Elbow?

A Welded Elbow is a standard elbow fitting that is permanently welded to the pipe, ensuring a leak-proof and strong connection. Unlike threaded or flanged elbows, welded elbows provide enhanced structural integrity, making them ideal for high-pressure and high-temperature applications.

Key Features of Welded Elbow:

- Seamless connection: No risk of leakage due to welding.

- Highly durable: Withstands extreme temperatures and pressure.

- Available in different materials: Stainless steel, carbon steel, and alloy steel.

- Common angles: 45°, 90°, and 180° bends.

- Widely used in: Power plants, steam pipelines, and heavy-duty industrial piping.

Comparing Reducing Elbow vs. Welded Elbow

| Feature | Reducing Elbow | Welded Elbow |

|---|---|---|

| Function | Changes pipe size & direction | Changes only direction |

| Connection Type | Can be welded, threaded, or flanged | Only welded |

| Leak Resistance | Moderate | High |

| Durability | High | Very High |

| Common Applications | Water treatment, chemical, and HVAC systems | Oil & gas, power plants, and steam pipelines |

Which One Should You Choose?

- Use a Reducing Elbow: when you need to connect different pipe sizes while redirecting flow in a compact space.

- Choose a Welded Elbow: when your system demands high strength, leak-proof, and long-lasting connections in high-pressure environments.

Conclusion

Both Reducing Elbows and Welded Elbows serve essential roles in piping systems. Your choice depends on flow requirements, pressure conditions, and space availability. Selecting the right elbow ensures efficiency, safety, and longevity of the system.