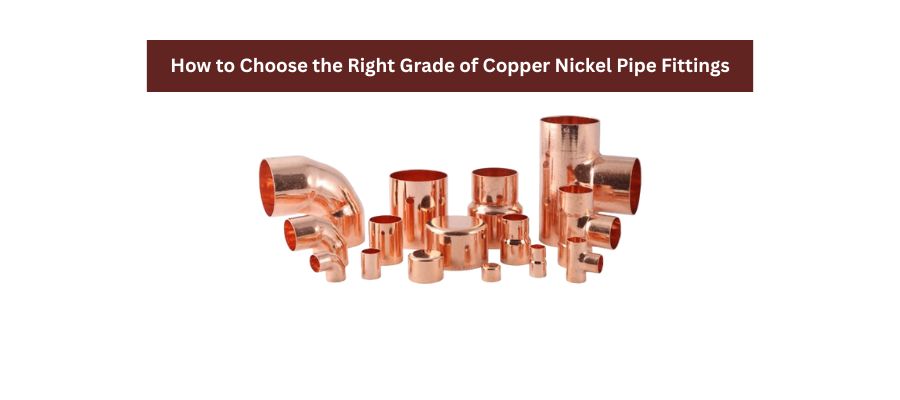

When working on a project that requires durable, corrosion-resistant, and long-lasting piping solutions, Copper Nickel Pipe Fittings are often at the top of the list. However, selecting the right grade for your application is crucial to ensure performance, safety, and cost efficiency. This guide by Max Pipes & Fittings Inc will walk you through everything you need to know to make the right choice.

1. Understanding Copper Nickel Alloys

Copper nickel, also known as cupronickel, is a group of alloys that primarily consist of copper and nickel, with small amounts of iron and manganese. These alloys are prized for their outstanding resistance to seawater corrosion, excellent thermal conductivity, and mechanical strength.

The two most common grades used in pipe fittings are:

- Cu-Ni 90/10 (90% copper, 10% nickel)

- Cu-Ni 70/30 (70% copper, 30% nickel)

2. Key Factors to Consider Before Selecting a Grade

a. Environmental Conditions

The environment where the fittings will be installed plays a huge role in determining the grade.

- Marine Environments: If your application involves seawater exposure, especially in shipbuilding or offshore oil platforms, 90/10 grade is highly effective due to its proven resistance to biofouling.

- High-Pressure or High-Velocity Seawater: For harsher marine conditions, desalination plants, and offshore oil rigs, 70/30 grade is preferred for its superior strength and resistance.

b. Pressure and Temperature Requirements

The grade you choose should match the operational pressure and temperature of your system.

- 90/10 grade offers adequate strength for general marine and industrial use.

- 70/30 grade is better suited for high-pressure pipelines and condensers in power generation plants.

c. Mechanical Strength

If your system demands higher tensile strength and durability under mechanical stress, the 70/30 alloy is more suitable. For moderate mechanical requirements, the 90/10 alloy is generally sufficient.

3. Common Applications and Grade Suitability

| Application | Recommended Grade | Reason |

|---|---|---|

| Shipbuilding & Marine Piping | 90/10 | Superior resistance to seawater corrosion |

| Offshore Oil & Gas | 70/30 | Handles high pressure and corrosive conditions |

| Desalination Plants | 70/30 | Resists erosion in high-velocity seawater |

| Heat Exchangers & Condensers | 70/30 | High thermal conductivity & mechanical strength |

| Industrial Cooling Systems | 90/10 | Cost-effective and corrosion-resistant |

4. Standards and Specifications

Ensure that the Copper Nickel Pipe Fittings meet relevant international standards. The most widely recognised specifications include:

- ASTM B466 – Seamless copper-nickel pipes and tubes

- ASTM B467 – Welded copper-nickel pipes

- MIL-T-16420K – Military specifications for marine-grade piping

Choosing fittings that comply with these standards guarantees quality, safety, and performance.

5. Cost vs. Performance

While both 90/10 and 70/30 grades offer excellent corrosion resistance, the 70/30 grade generally costs more due to its higher nickel content and increased mechanical strength. For budget-sensitive projects with moderate operating conditions, the 90/10 grade provides excellent value. However, for mission-critical applications in harsh environments, investing in 70/30 is worth the extra cost.

6. Welding and Fabrication Considerations

If your project involves on-site fabrication or welding, note that:

- Both grades are easily weldable without preheating.

- Proper filler metals should be selected to match the grade.

- The heat-affected zone must be carefully managed to maintain corrosion resistance.

7. Supplier Reliability

Working with a trusted manufacturer like Max Pipes & Fittings Inc ensures you receive fittings that meet strict quality control standards. Choosing the right supplier guarantees consistent material composition, precise dimensions, and reliable performance.

8. Steps to Select the Right Grade – Quick Checklist

- Identify the Application – Marine, industrial, offshore, or power plant.

- Evaluate Environmental Factors – Seawater velocity, salinity, and temperature.

- Check Pressure & Temperature Ratings – Match them to system requirements.

- Consider Maintenance Requirements – Higher grade alloys require less frequent replacement.

- Review Standards Compliance – ASTM, MIL, or equivalent certifications.

- Consult with Experts – Leverage the knowledge of experienced suppliers.

Conclusion

Selecting the right grade of Copper Nickel Pipe Fittings is a decision that directly impacts the efficiency, durability, and safety of your project. While 90/10 grade is perfect for most marine and general industrial uses, the 70/30 grade excels in high-pressure, high-velocity, and aggressive seawater environments. By considering environmental conditions, pressure requirements, and standards compliance, you can make a choice that balances performance with cost.

At Max Pipes & Fittings Inc, we provide high-quality Copper Nickel solutions that meet global standards, ensuring your project’s long-term success.