Industrial piping systems form the backbone of countless operations, from oil refineries and chemical plants to water treatment facilities and HVAC systems. To ensure smooth transport of fluids and gases, engineers rely on a variety of fittings that maintain direction, pressure, and efficiency within the pipeline. Among these fittings, 90 Degree Elbows play a critical role in improving flow efficiency while accommodating space and design requirements.

Understanding 90 Degree Elbows in Piping Systems

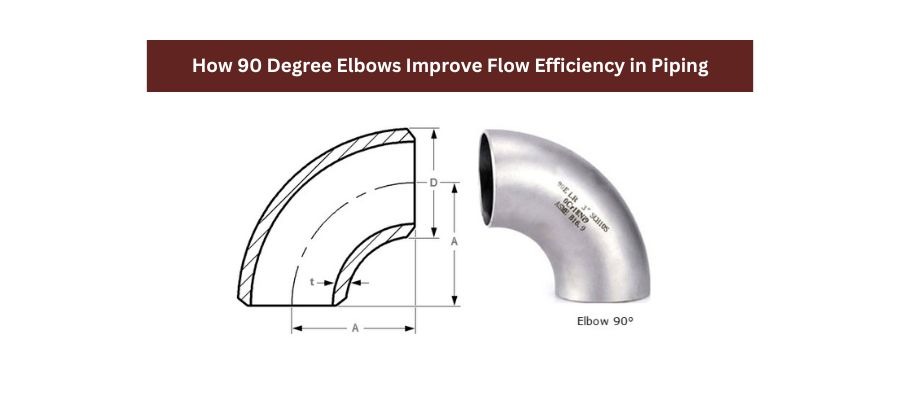

90 Degree Elbows are pipe fittings designed to change the flow direction by 90 degrees. Depending on the application, they can be manufactured with a long radius or a short radius. A long-radius elbow allows for a smoother change in direction, reducing friction and pressure drop, while a short-radius elbow is more compact and suitable where space is limited.

These fittings can be made from stainless steel, carbon steel, alloy steel, or non-metallic materials, ensuring they meet the requirements of diverse industries.

Importance of 90 Degree Elbows in Flow Management

The primary function of a 90-degree bend is not just to redirect the flow but also to maintain system integrity. Without elbows, piping systems would require awkward bends or welding angles that could compromise efficiency and safety. By using elbows, engineers can optimize layouts, prevent leakage points, and control flow turbulence effectively.

How 90 Degree Elbows Enhance Flow Efficiency

- Reduced Pressure Loss

Properly designed elbows, especially long-radius types, help minimize energy losses caused by sudden directional changes. This allows pumps and compressors to operate with less strain, improving the overall efficiency of the system. - Smooth Fluid Dynamics

Fluids and gases follow a streamlined path when guided through an elbow, reducing turbulence and ensuring consistent pressure. This is particularly important in high-velocity systems where sudden changes could cause vibration or erosion. - Optimized Space Utilization

Industrial plants often operate in confined areas. 90 Degree Elbows allow for compact pipeline designs without compromising flow performance, making them essential in plant layouts where space is at a premium. - Versatility Across Applications

Whether transporting steam, water, oil, or chemicals, elbows help regulate the flow and maintain safe operating conditions. Their adaptability ensures that the efficiency benefits extend across multiple industries.

Applications of 90 Degree Elbows in Industries

- Oil and Gas – For transporting crude oil, refined products, and natural gas with minimal flow resistance.

- Chemical and Petrochemical – For handling corrosive substances safely while maintaining smooth flow.

- Power Generation – For steam lines and cooling water systems where efficiency is critical.

- Food and Beverage – For hygienic piping systems requiring clean and efficient fluid transfer.

- HVAC Systems – For optimising air circulation in heating, ventilation, and cooling systems.

Factors Affecting Efficiency of 90 Degree Elbows

- Radius of Bend – Long-radius elbows are more efficient than short-radius ones due to reduced friction.

- Material Selection – Corrosion-resistant materials such as stainless steel ensure long-term efficiency.

- Pipe Diameter – Correct sizing helps maintain velocity and reduces pressure drop.

- Quality Standards – Compliance with ASME, ASTM, or ISO standards ensures performance consistency.

Advantages of Using 90 Degree Elbows

- Enhanced system reliability with fewer stress points.

- Flexibility in pipeline design for compact spaces.

- Reduced maintenance costs due to improved flow performance.

- Long service life, especially when manufactured with high-quality materials.

Conclusion

Efficiency in industrial piping is not achieved by pipelines alone but by the careful integration of fittings that regulate flow and direction. 90 Degree Elbows are indispensable in ensuring smooth, energy-efficient, and safe operations across industries. By reducing pressure losses, optimising flow dynamics, and allowing compact layouts, these fittings not only improve operational performance but also extend the life of the entire piping system.

When selecting elbows for any project, factors such as radius, material, and compliance with industry standards must be considered. Choosing the right 90 Degree Elbows ensures your industrial piping system operates with maximum efficiency, reliability, and longevity.