In piping systems, fittings are essential components that allow for the redirection, branching, or joining of pipes. Among the most commonly used pipe fittings are tees, which have three connection points and are shaped like the letter ‘T.’ Two specific types of tees—equal tees and reducing tees—serve different purposes in fluid distribution systems. Understanding the differences between these two types of tees is crucial for selecting the right fitting for a given application.

In this blog, we will explore the features, applications, and advantages of equal tees and reducing tees, providing a comprehensive comparison between them.

What is an Equal Tee?

An equal tee (also known as a straight tee) is a pipe fitting with three outlets of the same diameter. All three connection points, including the run and the branch, have the same size, ensuring that the flow rate remains consistent across all branches.

Key Features of Equal Tees:

- Same Diameter Outlets: All three outlets have identical diameters, making it easy to maintain consistent flow rates.

- Fluid Flow Distribution: Used to branch a pipe system, where fluid or gas is distributed equally across the branch.

- Uniform Flow: Ensures that the flow is not altered or reduced at the branching point, keeping the pressure and flow velocity stable.

Applications of Equal Tees:

- Plumbing Systems: Used in water distribution systems where equal flow to all branches is necessary.

- Chemical Processing: Ensures balanced fluid flow in pipelines that carry chemicals or gases.

- HVAC Systems: Commonly used in heating, ventilation, and air conditioning systems to distribute air or water uniformly across different outlets.

- Industrial Applications: Used in industries like oil and gas, power plants, and petrochemicals to maintain equal flow rates in branching pipelines.

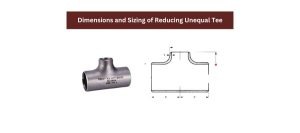

What is a Reducing Tee?

A reducing tee is a type of buttweld fitting where the branch outlet has a smaller diameter than the main run. The two outlets on the main pipe maintain the same size, while the third branch is smaller, allowing the fitting to connect pipes of different diameters.

Key Features of Reducing Tees:

- Different Diameter Outlets: The main run has two outlets of the same size, while the third branch has a reduced diameter.

- Flow Control: Allows for a change in pipe size and reduces the flow in the branch, ideal for systems that require varied flow rates or lower pressure in one branch.

- Versatile Functionality: Enables a smooth transition between different pipe sizes without the need for additional reducers or adapters.

Applications of Reducing Tees:

- Water Supply Systems: Used where the main water line branches off to smaller supply lines, such as in residential or commercial plumbing systems.

- Gas Distribution: Common in systems where gas flow needs to be reduced in certain areas, such as in industrial gas distribution networks.

- Irrigation Systems: Reducing tees are often used in agricultural irrigation systems to reduce the water flow to certain areas.

- Industrial Pipelines: In industrial applications, reducing tees allow different flow rates for various processes within a single system, optimizing efficiency and reducing the need for additional equipment.

Equal Tee vs Reducing Tee: Key Differences

- Outlet Size:

- Equal Tee: All three outlets are of the same diameter, ensuring equal flow throughout the system.

- Reducing Tee: The branch outlet has a smaller diameter than the main run, allowing for a reduction in flow or pressure to one part of the system.

- Flow Distribution:

- Equal Tee: Fluid flow remains constant across all three outlets, providing uniform distribution without altering flow rate or pressure.

- Reducing Tee: The smaller branch reduces the flow or pressure, making it ideal for applications where the flow needs to be directed into smaller pipes or systems.

- Functionality:

- Equal Tee: Primarily used when maintaining consistent flow across all outlets is essential, typically in systems where balance and uniformity are key.

- Reducing Tee: Used when there is a need to connect different pipe sizes and to manage varying flow rates across the system.

- Applications:

- Equal Tee: Common in systems that require equal flow distribution, such as in HVAC, plumbing, and industrial fluid control systems.

- Reducing Tee: Ideal for systems that require flow reduction in one branch, making them suitable for water supply, gas distribution, and irrigation systems.

- Installation Considerations:

- Equal Tee: Simple to install since all outlets are of the same size, which means fewer components are required during installation.

- Reducing Tee: Slightly more complex to install as it involves different pipe sizes, requiring precise alignment and flow calculation to ensure proper pressure and flow management.

Advantages of Equal Tees

- Uniform Flow Distribution: Ensures consistent pressure and flow across all outlets, making them suitable for systems where equal flow is essential.

- Simple Design: The straightforward design allows for easy installation and maintenance in systems that require balanced fluid distribution.

- Wide Range of Applications: Can be used in almost any industry, including plumbing, HVAC, chemical processing, and water treatment.

Advantages of Reducing Tees

- Versatile Connections: Reducing tees provide the ability to connect different pipe sizes, simplifying complex systems with varying flow needs.

- Flow Control: Helps manage pressure and flow by reducing the diameter of the branch outlet, offering more control over fluid distribution.

- Cost-Effective: By eliminating the need for extra reducers or adapters, reducing tees streamline the piping system and reduce overall material costs.

Conclusion: Which Tee to Choose?

The choice between an equal tee and a reducing tee depends on the specific needs of your piping system. If you require uniform flow and pressure across all outlets, an equal tee is the ideal choice. This makes it perfect for HVAC systems, water distribution networks, and industrial processes where balanced flow is essential.

On the other hand, if your system involves pipes of different diameters or requires a reduction in flow or pressure in one branch, a reducing tee will provide the flexibility and control you need. Reducing tees are commonly used in gas distribution, water supply systems, and irrigation setups.

Both fittings play essential roles in fluid distribution systems and offer unique benefits based on their designs and functions. Understanding their differences helps you make the right decision for your piping system, ensuring optimal performance and efficiency.